PRODUCTS

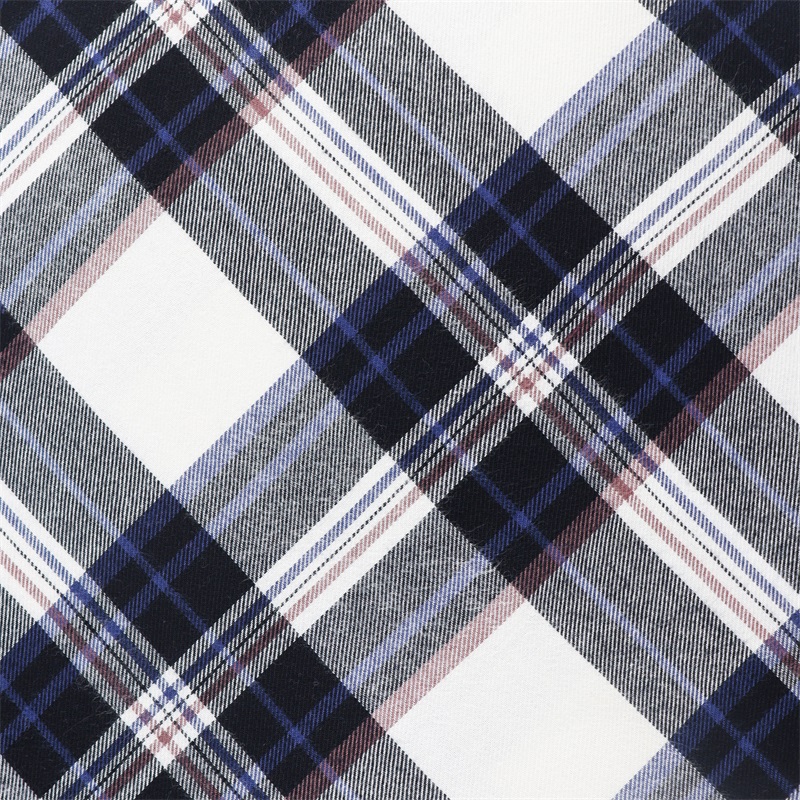

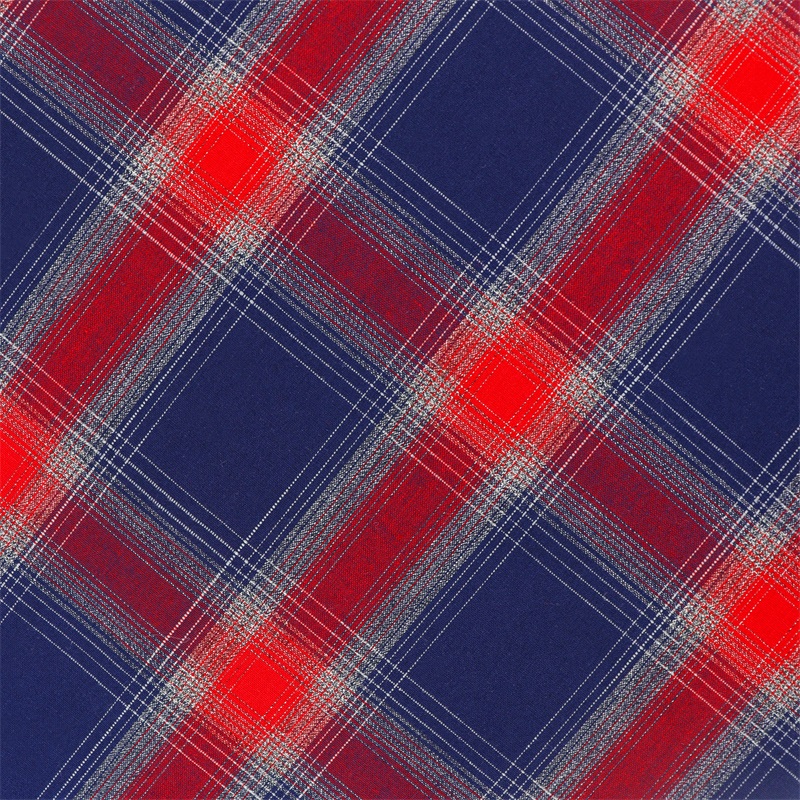

Factory Source Cotton Silk Fabric - China Wholesale Light Weight 90GSM Melange cotton Check Woven Fabric – Lvbajiao

Factory Source Cotton Silk Fabric - China Wholesale Light Weight 90GSM Melange cotton Check Woven Fabric – Lvbajiao Detail:

| Technics | Woven |

| Thickness: | Light Weight |

| Type | Plain Weave Fabric |

| Use | Garment, Shirts & Blouses |

| Color | Customized |

| Supply Type | Make-to-Order |

| MOQ | 2200yards |

| Feature | Soft/High color fastness/Custom pattern |

| Applicable to the Crowd: | WOMEN, MEN, GIRLS, BOYS |

| Certificate | OEKO-TEX STANDARD 100, GOTS |

| Place of Origin | China (Mainland) |

| Packaging Details | Packing in rolls with plastic bags or base on your requirement |

| Payment | T/T,L/C,D/P |

| Sample Service | Hanger is free,handloom should be paid and courier charge need to be collected |

| Customized Pattern | Support |

Color spinning can complete the fuzzy three-dimensional effect and texture that cannot be achieved by white blank dyeing. Color spinning is pollution-free and can control color difference to the greatest extent. Therefore, color-spun yarns that are soft and fashionable in color and can cope with small batches and various types of flexible production are increasingly used in mid-to-high-end apparel products.

Because of the new process of “dyeing first, spinning later”, color spinning has shortened the production process and production cost of downstream processing enterprises, and has higher added value. Compared with the traditional “spinning first and then dyeing”, color spinning Technology, color spinning products function better than other textile products, have strong market competitiveness and better market prospects.

1. The color spinning shows a variety of colors on the same yarn, which is rich, full and soft. The fabrics woven with colored yarns have a vague three-dimensional effect, with subtle colors, natural and layered.

2. The dyeing and spinning production process of color-spun yarn saves more than 50% of water and reduces emissions compared with traditional processes, which meets the requirements of low-carbon and environmental protection. To produce an ordinary garment, color spinning can save 4 kilograms of water. If in the past year, all textiles in our country use color spinning, it will save 50 million tons of water.

3. The dyeing process of color spinning is common, and it has high technological content in fiber dyeing, color matching and multi-fiber blending. The birth of more new fabrics has promoted the geometric product growth of clothing and home textile products.

In the entire textile industry, traditional crafts account for about 65%, dyed yarns are about 20%, and colored yarns are about 15%. At present, production is still driven by circulation. If production is driven by consumption in the future, the prospect of colored spinning will be immeasurable.

Product detail pictures:

Related Product Guide:

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our greatest general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for Factory Source Cotton Silk Fabric - China Wholesale Light Weight 90GSM Melange cotton Check Woven Fabric – Lvbajiao , The product will supply to all over the world, such as: Norwegian, Japan, Sheffield, Our company adheres to the spirit of "lower costs, higher quality, and making more benefits for our clients". Employing talents from the same line and adhering to the principle of "honesty, good faith, real thing and sincerity", our company hopes to gain common development with clients from both at home and abroad!

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.